ABB Emax moulded case circuit breakers (MCCB)

Introduction to circuit breaker

A circuit breaker is protective device which is designed to automatically open an electrical circuit thus preventing harm and damages to equipment and personnel.

The damages are due to over load, short circuits and sometimes earth faults.

Circuit breakers are made in varying sizes, from small devices which carry fractional amperes (e.g. a 10 milli-ampere residual circuit breaker) like that in a typical house up to extremely large ones like a

generator circuit breaker which continuously carry few tens of thousands of amperes.

An LV/MV system Circuit breaker is similar to its fuse counterpart in its main function of fault interruptions.

However, a circuit breaker differs from a fuse in its other function which are breaking loads as well as normal opening with or without current in the circuit.

Further, it performs closing function and is nondestructive to itself (except requiring periodic maintenance, replacement of current interrupting contacts and in some forms becomes a device that needs a part of it to be replaced after specific numbers of operations). A fuse however, operates once and then has to be replaced, a circuit breaker can be reset (either manually or automatically) to resume normal operation.

An early form of circuit breaker was described by T.A. Edison in an 1879 patent application.

Inside a Circuit Breaker

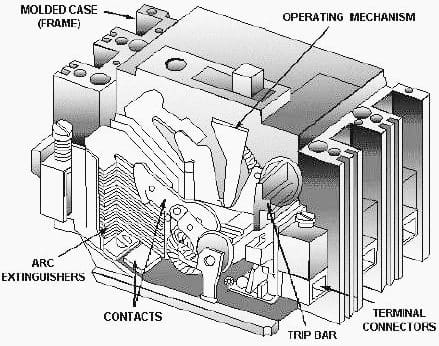

Moulded case circuit breake (MCCB) parts

There are two attributes to electricity which is quite apparent due to its obviousness to the real world which are the Current and the Voltage as well as some functional derivative of these two like Real power (Watt),Reactive power (VAR), Energy (kWH) etc.

Well something is much complicated as if you get into the micro-micro world of it in terms of particles which follow electrical and magnetic field forces. Performance of a circuit breaker in its main function relates with making, carrying and breaking currents in an Electrical circuit.

To make or break a circuit there must be some component which connects and disconnects which is called Contacts/interrupters. While making a circuit the components (one or both or many has to move in an Electric field) and since the movement is to make a circuit, the field gets progressively increased as the components move and we can imagine a pre-arc (prestrike). While breaking, it is opposite thing and we imagine a restrike.

Voltage and currents are related same way as an Electric field (due to available static electric charge) with a Magnetic field (due to moving Electric charge).

Well we got it… all matter (other than total vacuum) reacts (interacts) to these two fields fairly easily. How they react is another matter… too complicated?

An AC circuit (and for that matter a DC circuit too for part) has components which perform Magnetic and polarizing functions. Thus, they introduce a time factor into the straight forward relationship between Voltage and Current.

The point we got now is clear, a circuit breaker needs to withstand voltage (withstand of Electric field of dielectric between contacts) without breaking down insulation between the contacts when they are stationary (in open position), while moving to close and break circuits and shall make, carry or break currents while contacts are stationary (in closed position) and while they are breaking or making.

The current again has two aspects one is due to the heat it causes (which is proportional to the square of it) and electromagnetic forces.

Some more parameters gets added since circuit breakers are often linked in some way with neighboring circuit components, or magnetic devices (like motors, welding etc) which introduces switching transients and atmosphere (lightning transients). These are actually are called impulses (surges) and have a characteristic front, peak and tail of a definite polarity (+ve or negative).

Some others may be oscillatory (decaying, steady, increasing) which can be for the sake of study and computation addressed as a function of the fundamental part (frequency 50Hz. 60Hz etc).

Thus we added Impulse withstand requirement for a circuit breaker, reactive (capacitive/inductive) duty and harmonics performance.

We can now imagine what might be happening inside a large EHV circuit breaker while it is performing its operation. Fault currents could be few hundreds of thousands at extremely high potential …amount of heat, forces could be enormous.

A blast of an explosive (like TNT) heats up surrounding air and displaces it in a shock wave which is hot, blinding and deafening and catastrophic reactions to the unlucky ones closeby to it…incinerating, vaporizing matter in a fraction of a second, now we imagine few tons of TNTs exploding simultaneously… that’s what will be like inside it.

I have made a point that dynamic forces are quite important when we deal with large currents.

Operation of a Circuit Breaker

Thermal-magnetic circuit breakers employ a bi-metalic strip to sense overload conditions.

All circuit breakers have common features in their operation, although details vary substantially depending on the voltage class, current rating and type of the circuit breaker. To breaking a fault, firstly a fault condition needs to be detected. For higher capacity CBs this function is delegated to external Protective devices due to size, proximity to High volatges, sophistication in detection of all types of faults accurately to specific requirement of time.

In low-voltage circuit breakers this is usually done within the breaker enclosure.

Circuit breakers for large currents or high voltages have

tripping means and separate closing means. These may be magnetic solenoids, spring charged or release of some sort of energy by auxiliary means (pneumatic, hydraulic etc). A trigger is usually based on applying a battery, voltage…..some hydraulic devices may derive it by the dielectric media itself (Hydraulic pole-top reclosers which are common in distribution feeders), puffer mechanism or by means of power current transformers etc.

Thus we identified that some operation mechanism(s) is/are required.

To perform in a small space with cost effective and efficient way against demanding forces and heat we can imagine special design is required to confine it to limited area within a CB. So we identified some interrupting means. Once a fault is detected, contacts within the circuit breaker must open to interrupt the circuit; some mechanically-stored energy (using something such as springs or compressed air) contained within the breaker is used to separate the contacts, although some of the energy required may be obtained from the fault current itself. Small circuit breakers may be manually operated; larger units have sophisticated to trip the mechanism, and electric motors to restore energy to the springs.

The circuit breaker contacts must carry the load current without excessive heating, and must also withstand the heat of the arc produced when interrupting the circuit. Contacts are made of copper or copper alloys, silver alloys, and other materials.

Service life of the contacts is limited by the erosion due to interrupting the arc. Miniature and molded case circuit breakers (

MCB and MCCB) are usually discarded when the contacts are worn, but power circuit breakers and high voltage circuit breakers (HVCB) have replaceable contacts. When a current is interrupted, an arc is generated. This arc must be contained, cooled, and extinguished in a controlled way, so that the gap between the contacts can again withstand the voltage in the circuit.

Different circuit breakers use vacuum, air, insulating gas, or oil as the medium in which the arc forms.

Different techniques are used to extinguish the arc including:

- Lengthening of the arc

- Intensive cooling (in jet chambers)

- Division into partial arcs

- Zero point quenching

- Connecting capacitors in parallel with contacts in DC circuits

Finally, once the fault condition has been cleared, the contacts must again be closed to restore power to the interrupted circuit.

Resource: Circuit Breakers (CBs) in Power Systems by S.R. Javed Ahmed